Bromma Accident Prevention System

Safety in the cargo handling industry incorporates many aspects, and of them is ensuring equipment’s safety as it has a direct effect on the efficiency of operations. Preventing potential equipment-related accidents can minimize the risk of injuries, damaged equipment, and all indirect costs related to downtime. Investing in accident preventive solutions can be small in relation to operational gains in the long run.

Throughout the years Bromma has been developing accident prevention applications for the yard, quay, and mobile harbour cranes. These solutions provide controls over accident risks and dangerous situations with the help of alert and indication systems. Additionally, they provide Increased safety connection between spreaders and attachment, e.g. the headblock and overheight frame and enhanced controls on twistlock lock/unlock functions. Below you can see the list of accident prevention solutions and their description.

Bromma Accident Prevention Systems includes the following options:

(Read the descriptions below the table)

STS45  |

Yard |

MHC |

|

| Flipper Up/Down Indication System | ✔ |

✔ (yard spreaders with flippers option) |

✔ |

| Landed Hold Indication System | ✔ | ✔ | ✔ |

| Redundant Telescopic Position Indication System | ✔ |

✔ (yard spreaders with PLC option |

🗶 |

| Headblock Connected Indication System |

✔ (shafts headblock connection only) |

✔ (shafts headblock connection only) |

🗶 |

| Instability Indication System | 🗶 | 🗶 | ✔ |

| In-Ship Cells Indication System | ✔ | 🗶 | 🗶 |

| Overheight Frame (OSR) Connected Indication System |

✔ (spreaders with |

✔ (spreaders with |

✔ (spreaders with |

| Twin-Twenty Detection System (TTDS) | ✔ | ✔ | ✔ |

| Height Indication System (HIS) | ✔ | ✔ | ✔ |

| Load Sensing Indication System | ✔ | ✔ | ✔ |

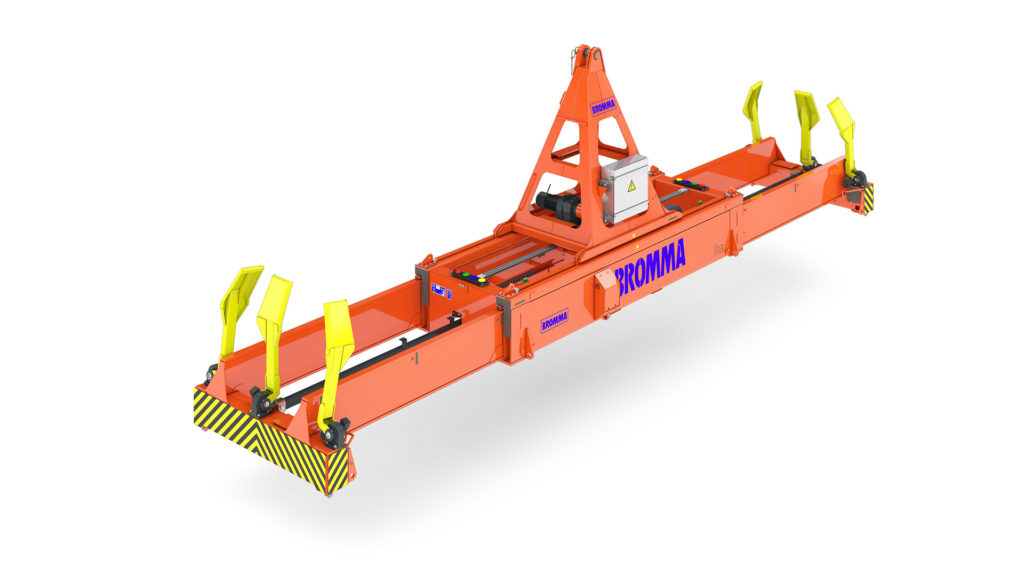

Flipper Up/Down Indication system

The Flipper Up/Down Indication System sends flipper position signals to the crane to smoothen the flipper control operations while handling containers. This helps to prevent accidents

while the flipper is moving or is at down position. The Flipper Up/Down Indication System is available as an option for spreaders equipped with hydraulically or electrically movable flippers.

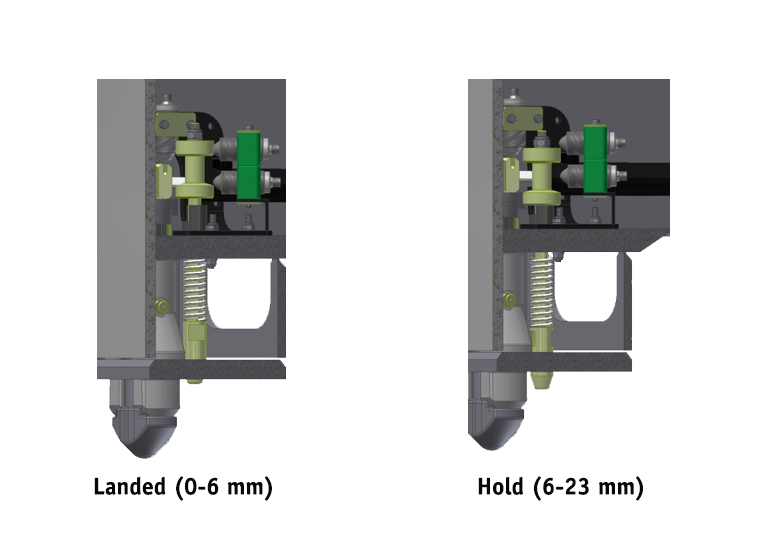

Landed Hold Indication System

The Landed Hold Indication System is an option to ensure that the spreader twistlocks are locked on properly to the container during a container move. During a lifting operation, the system will send a warning signal if the twistlocks are locked but are not lifting the container in any of the corners.

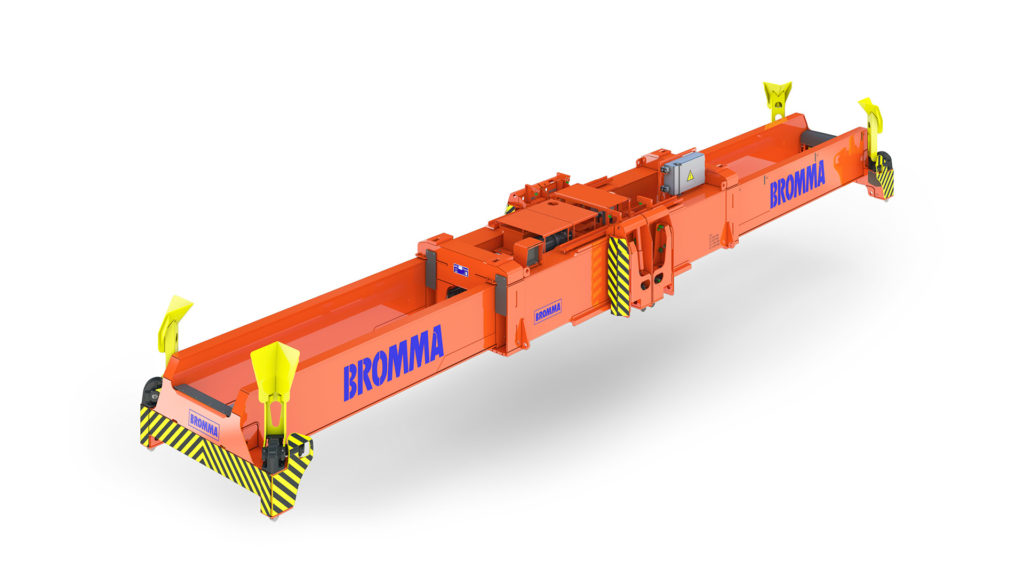

Redundant Telescopic Position Indication System

Telescopic positions on Bromma spreaders are as standard controlled by either proximity sensors or an encoder depending on the spreader model. It would be possible to have both or a Redundant Telescopic Position Indication System to reduce spreader downtime. The Redundant Telescopic Position Indication System is available as an option for ship-to-shore and yard spreaders with the PLC control.

Headblock Connected Indication System

The Headblock Connected Indication System sends out a signal when the headlock is connected to the spreader.

It is available as an option for spreaders with headblock connection to shafts. However, it is not available for other headblock connection types.

Levelling Control Indication System

The spreader Levelling Control Indication System is a self-contained level controller which is used to detect the degree and direction of an unlevelled platform condition. It then provides an output signal to the crane to relevel the platform plane. The Levelling Control Indication System is available as an option for Mobile Harbour Crane (MHC) spreaders.

In-Ship Cells Indication System

In-Ship Cells Indication System sends signals when the spreader is inside the ship cells and prohibits telescoping, twin separating, and flipper down movements to avoid accidents while the spreader in the ship cells. The system is available for all ship-to-shore spreaders.

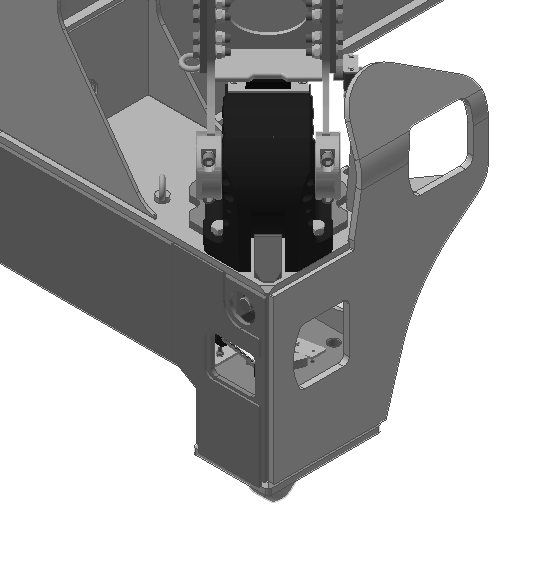

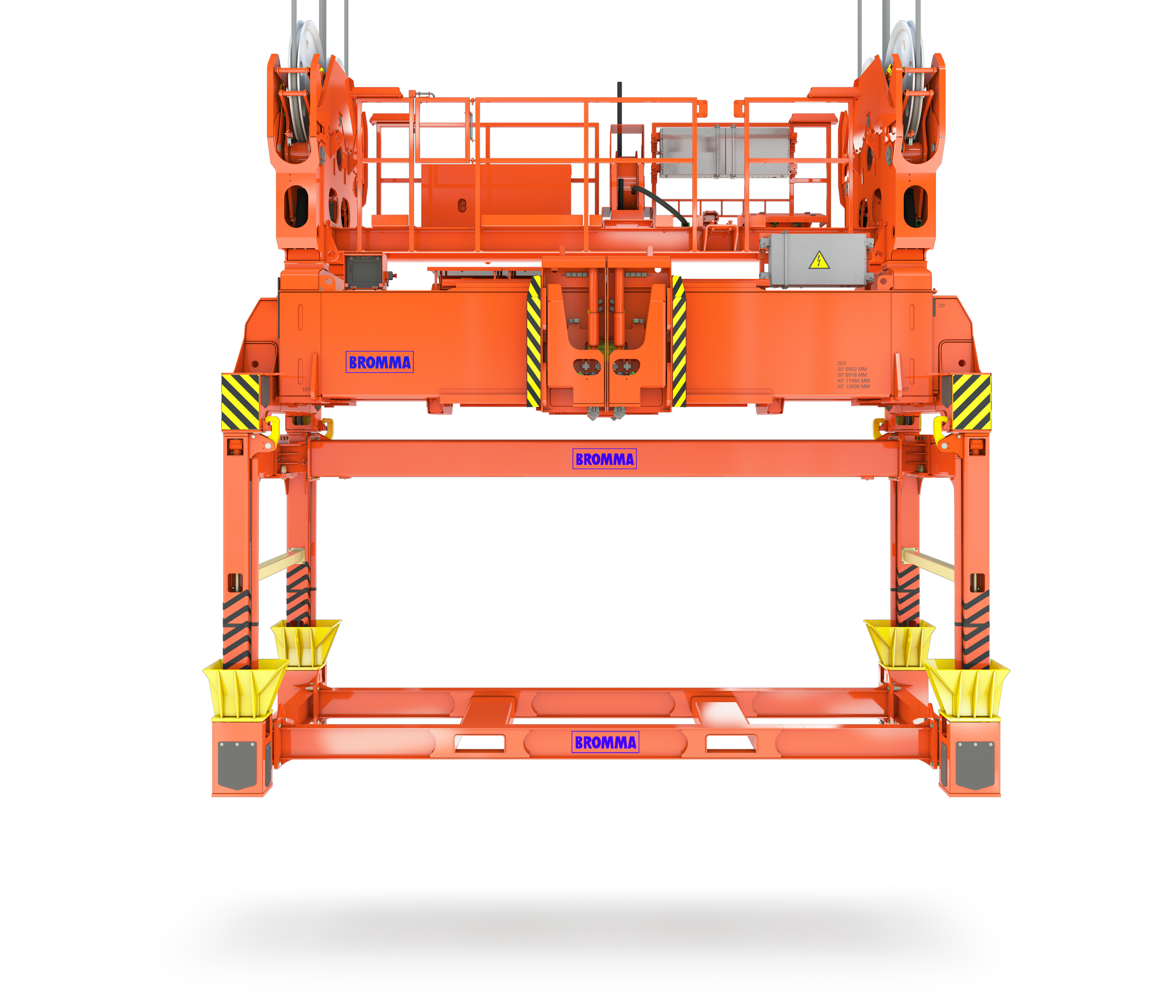

Overheight Frame (OSR) Connected Indication System

The Overheight Frame (OSR) Connected Indication System confirms that the Overheight Frame is latched under the spreader to ensure the safety of the Overheight Frame handling.

The Overheight Frame (OSR) Connected Indication System is available as an option for spreaders with lugs.

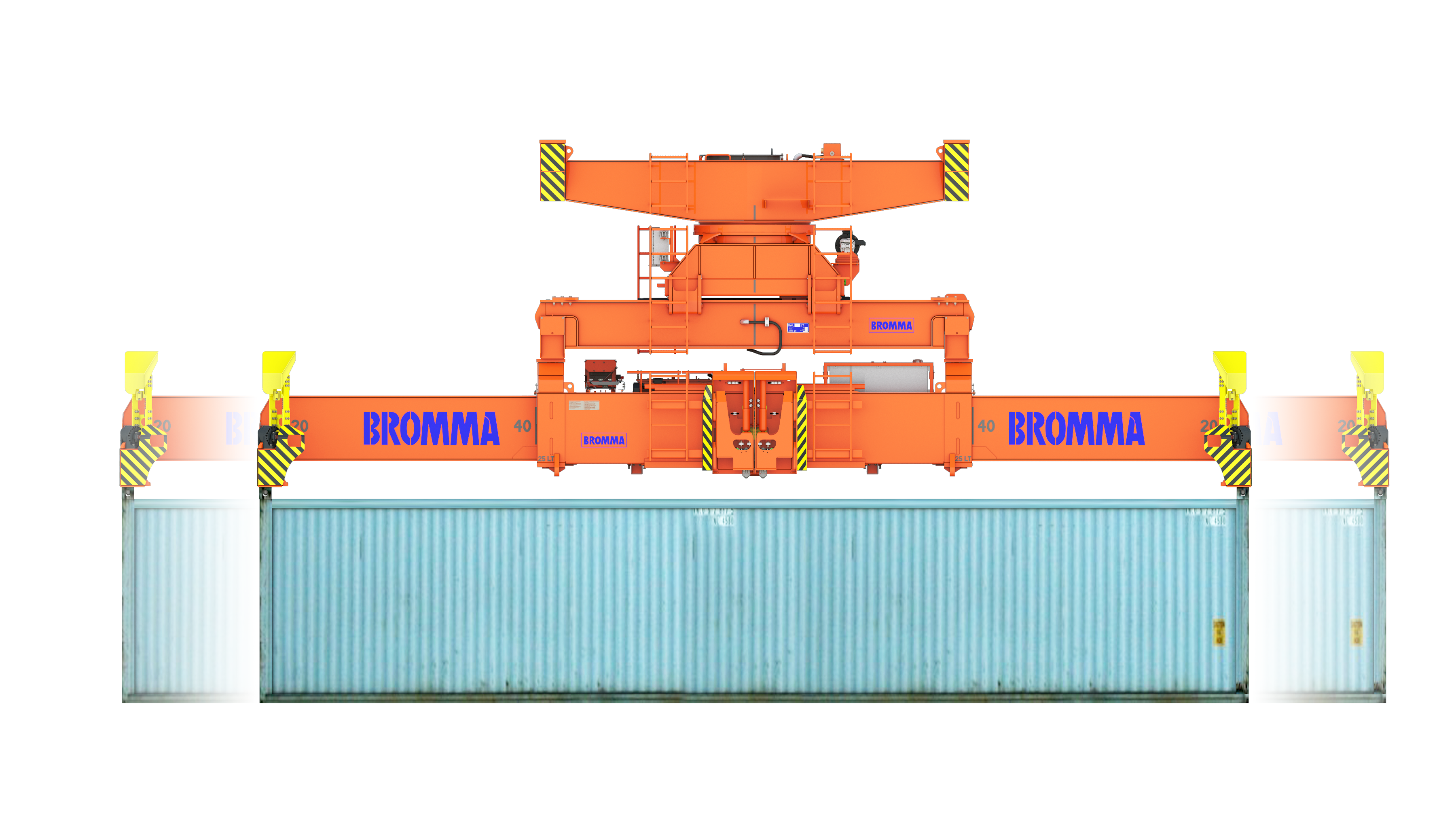

Twin-Twenty Detection System (TTDS)

The Bromma Twin-Twenty Detection System (TTDS) assists crane operators in detecting dangerous situations of two 20 the foot containers under a spreader positioned in the 40 foot

position which is a potentially risky and dangerous lifting situation. The system helps avoid twin-twenty accidents that potentially cause damage to containers and spreaders, and also reduces the risk of possible injuries. The TTDS can be easily adapted and is available as an option for all spreaders.

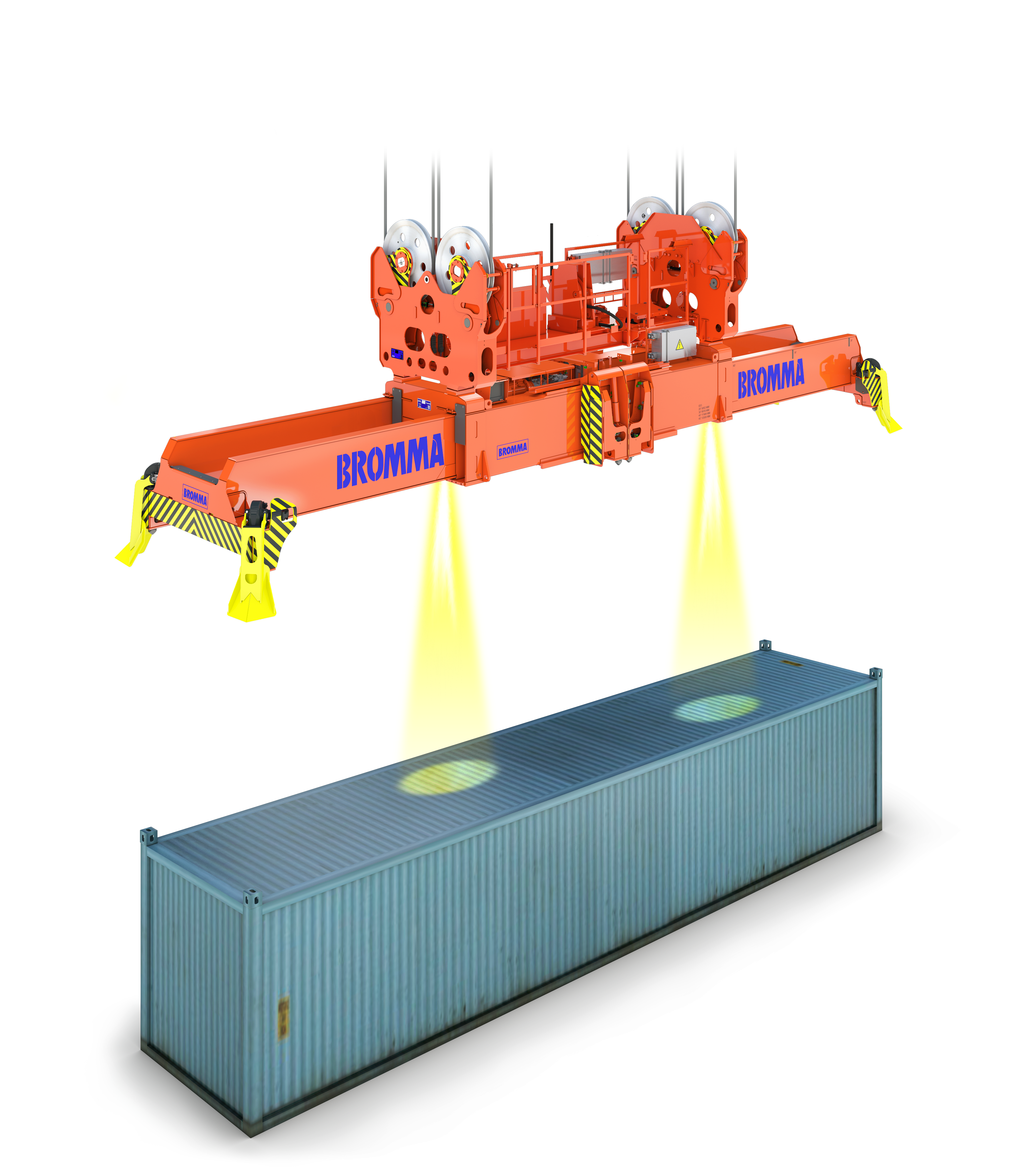

Height Indication System (HIS)

The Bromma ultrasonic Height Indication System (HIS) measures the distance between the spreader and the container, sending signals to the crane to decelerate or help the crane operator to avoid hard landings on containers. This can help to avoid slack ropes, and reduce the wear and tear on the spreader. The system is invaluable when landing in the ship cells, where it is much harder for the crane operator to visually gauge the remaining distance, or in jib-crane spreaders, where the crane cab is far away from the vessel. The HIS increases productivity and safety at a reasonable cost. The HIS can be easily adapted and is available as an option for all spreaders.

Load Sensing System

The Bromma Load Sensing System increases safety during operations by providing certified and accurate weighing suitable for container weight verification, overload detection and eccentric lift detection. The Bromma Container Weighing system is certified (Type Approved) to OIML R51 as well as to 2014/32/EU (MID).