Ports in Europe are under EU Climate Law obligated to cut down their CO2 emissions by 2030. And with Europe’s leading example, the rest of the world is likely to follow suit.

The environmental requirements for the container terminal industry are still limited to the direct aspects and effects of the products supplied. However, from a holistic sustainability perspective, the processes and materials used for producing the equipment are equally important.

In Bromma, we are committed to making this green transition possible for our clients through our own actions and products.

We have developed an all-electric ship-to-shore spreader that reduces both port’s energy consumption and CO2 emissions. However, the emission reduction potential of a terminal using any kind of spreader may be compromised by decisions made during the spreader’s production.

In this blog, we focus on the decisions related to the spreaders’ production phase. What are Bromma spreaders made of and how? And what are the implications for our spreaders’ environmental footprint compared to some alternatives?

The origin of steel

While steel is made all over the world, it is not always produced in a similar way or with similar materials. Likewise, there are different ways to produce the large amount of energy that is needed in steel production.

This means that steel production has varying levels of environmental impact. That impact is dependent on two primary factors: the source of the electricity used in the steel mill, and the type of iron ore. That’s why understanding the steel production process is paramount in getting a full picture of the emission footprint that different manufacturers in the steel industry have.

Next, we’ll tell you why Bromma spreaders are produced using European steel.

Location matters

An important factor determining the environmental footprint of steel is the source of the electrical power used in steel mills. Emissions from coal-fired steel production are dramatically higher than the emissions from a steel mill using other sources of energy, such as nuclear- or hydropower.

To a large extent, the choice of location defines the source of energy used. This makes the choice crucial. In China, steel production relies on energy that is mostly powered by coal. In contrast, the energy for European steel production is produced largely by nuclear- and hydropower. This fact is one of the reasons why we at Bromma have decided to use steel produced in Europe.

But there’s more. The source of the raw material, the iron ore itself, also plays an important role in steel manufacturing.

Based on where it is mined, the iron ore used to produce steel is either magnetite or hematite. Ore mined in northern Europe has high iron content and consists mainly of magnetite. What sets it apart from hematite, is that it can be processed through oxidation. The oxidation process generates large amounts of heat and hence requires less supplemental heat from other energy sources such as fossil fuels.

Thus magnetite is the option with considerably lower carbon emissions and energy consumption – and a natural choice for Bromma spreaders.

Why European steel is Bromma’s choice

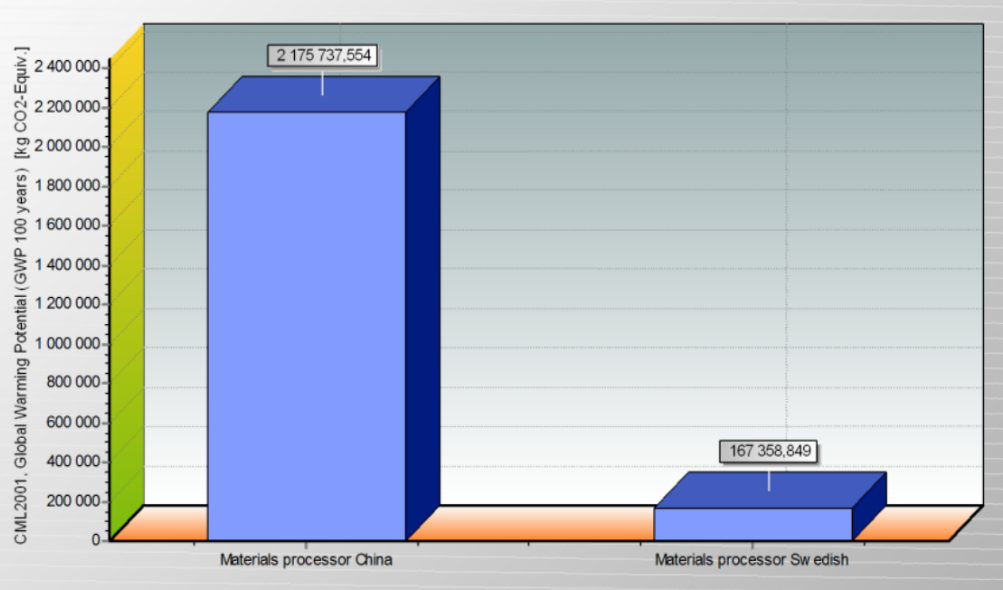

When considering both the energy source and the consistency of the iron ore, the difference in carbon emissions between European and Chinese steel is dramatic.

Even when factoring in the environmental emissions associated with shipping the steel from Europe to the Bromma production facility in Malaysia, the difference is significant.

In all, crane spreaders made from Chinese steel produce ten times more greenhouse gasses during the spreader production process compared to spreaders made from European steel. This difference is visualized in Figure 1 below.

Figure 1: An analysis of the emissions difference between a crane spreader produced using Chinese steel and a crane spreader produced using European steel

Together toward a greener tomorrow

Our aim is to help our customers decrease their carbon footprint and reach their sustainability goals.

We have a policy to proactively approach any environmental issue. We’ll do this by developing solutions to enable a low-carbon economy and by minimizing the environmental impact of our operations and products. The way to do that is to consider the whole life cycle of our products from their materials and design to their operating time and recycling.

By partnering with Bromma, you can be confident that you are investing in the environment of tomorrow.

Join the journey toward a better future!