Bromma Autolubrication System is a solution for optimizing spreader lifetime and reducing downtime. This system is designed to automatically lubricate critical areas on the spreader while it is in operation, resulting in a reduction of grease consumption by up to 50% and eliminating the need to manually lubricate each lubrication point.This leads to reduced service and maintenance, and lowers spreader downtime. The system is a highly recommended option for automated terminals designed to reduce downtime and prolong the spreader service period. When upgrading your spreaders with Bromma Autolubrication System you can expect:

- Grease consumption reduced by up to 50%

- Increased spreader service period as spreaders are lubricated while in operation

- Lower repair and maintenance costs due to less manual work

- The predetermined lubrication cycle can be adjusted to accommodate a terminal’s needs

- Suitable for heavy duty operations

The Autolubrication system status and notifications are also now available directly in Bromma Spreader Monitoring System (SMS).

How does it work?

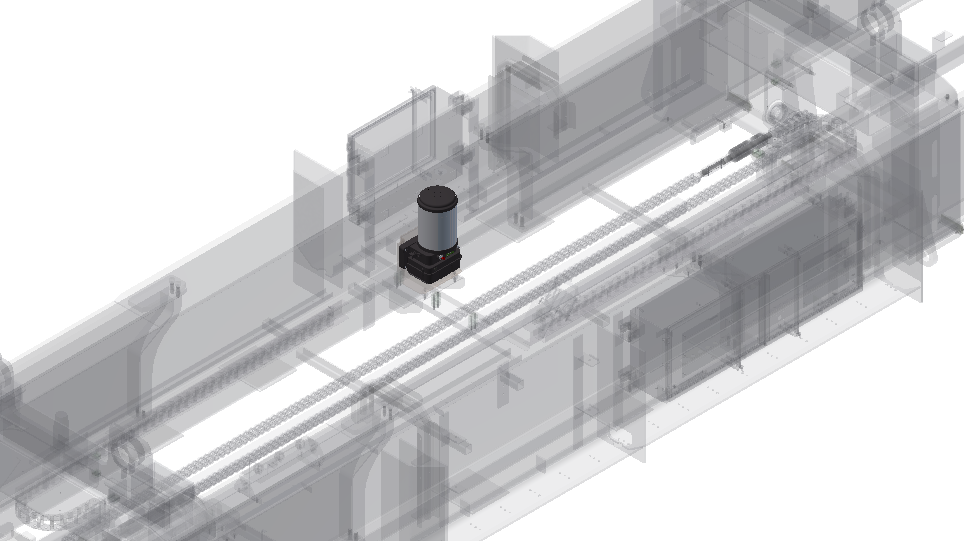

The system consists of a twin dual-line fully monitored lubrication system made up of a pump that comes with a grease reservoir, a main line network connected to the distribution blocks with metering units, and a secondary line network connected to the lubrication points. The grease is pumped to the distribution blocks via a double main line network. The metering units supply the exact amount of grease required to each of the lubrication points. The pump switches off once the pressure in all the metering units reach at least 175 bar.

The reservoir is equipped with a pressure switch to monitor the lubricant level while the electric pump is connected by two feedlines to a main distributor block which is then connected to sub-distributor blocks. These blocks feed individual lubrication points, which include the glide plates for telescopic beams, twin boxes (only for twin-lift spreaders), bearings, twistlocks, and chains.

The Auto Lubrication System can be made available as an upgrade option for spreaders already in operation. For details on available models for upgrade, please, contact your local Bromma representative. Upgrade your terminal with the Bromma Autolubrication System today and experience the benefits for yourself.