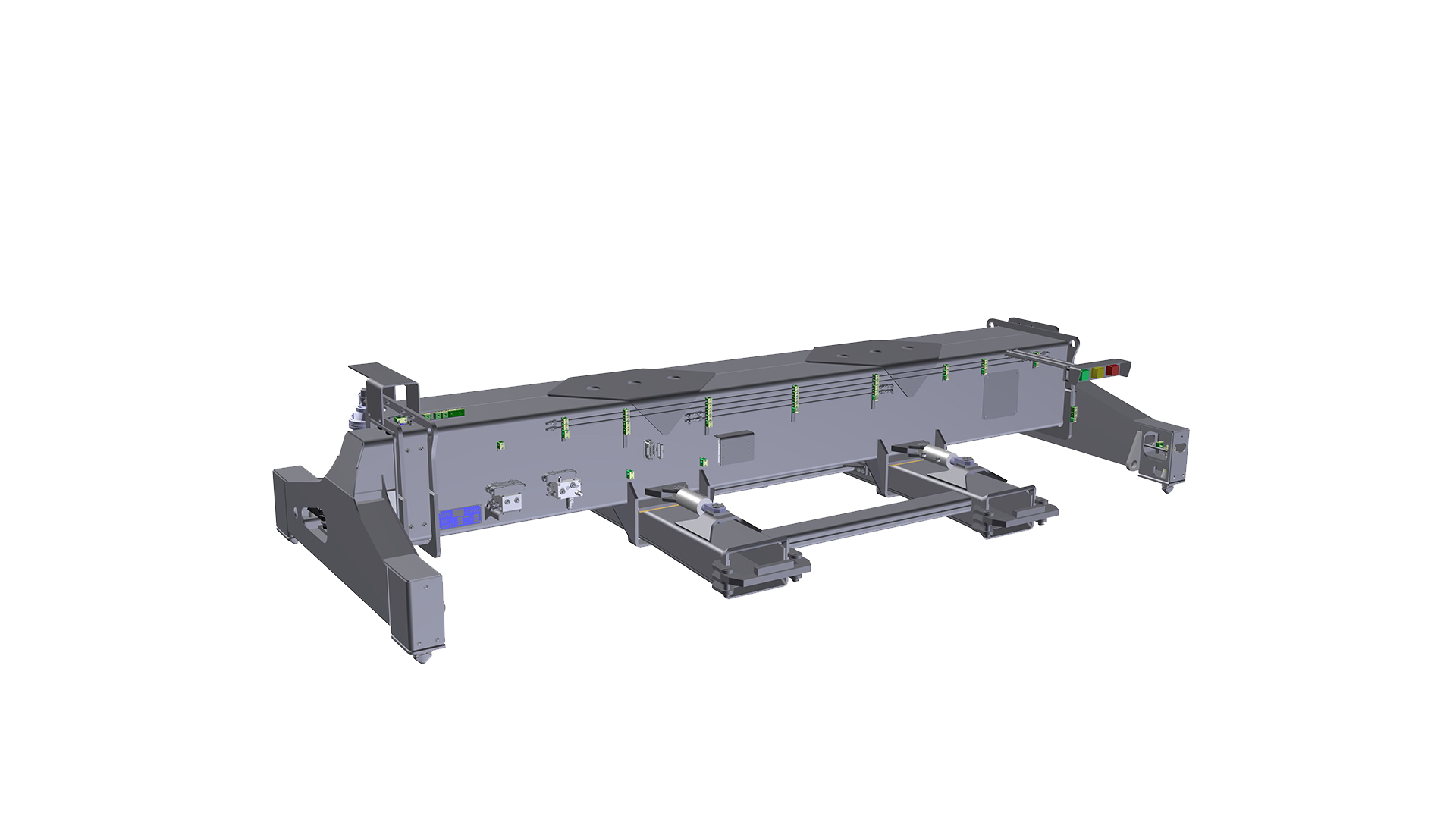

TLF40

Description

The spreader is designed with fork pockets to fit standard or inverted forks. It is latched onto the heels of the forks by pivot arms secured with pins. The TLF40 is equipped with slew, telescopic, reach mechanical pile slope and floating twistlock functions that allows it to easily locate containers. Additional tilt and side shift are provided by the fork lift truck.

All spreader movements are controlled with 24V proportional valves, providing precise and smooth operation. The spreader is operated from the driver’s cab over serial communication (CANopen) or parallel wiring. Commands are processed by an Electronic Control Unit on the spreader with built in safety logics for container handling.

The spreader is designed in accordance with EN13001. As all Bromma spreaders it is made from European high quality steel, which ensures a light and robust design. The spreader has a user friendly design and all components are easily accessible for inspection and maintenance.

Specifications

Lifting capacity (SWL)

- 45 metric tons, ±10% eccentric loading

- 4 x 10 metric tons, with lifting lugs on twistlocks endbeams

Tare weight

- 5 000 kg, without extra equipment

- 5 900 kg with slew and reach intermediate carriage

ISO floating twistlocks

- 90° in less than 1,5 sec. Mechanical & electrical safety interlock system.

Slew

- ± 3° with smooth control technology

Reach

- ± 50 mm with smooth control technology

Side shift

- On fork lift truck

Mechanical pile slope

- ± 5°self leveling with 4 telescopic hangers