Container Weighing

Description

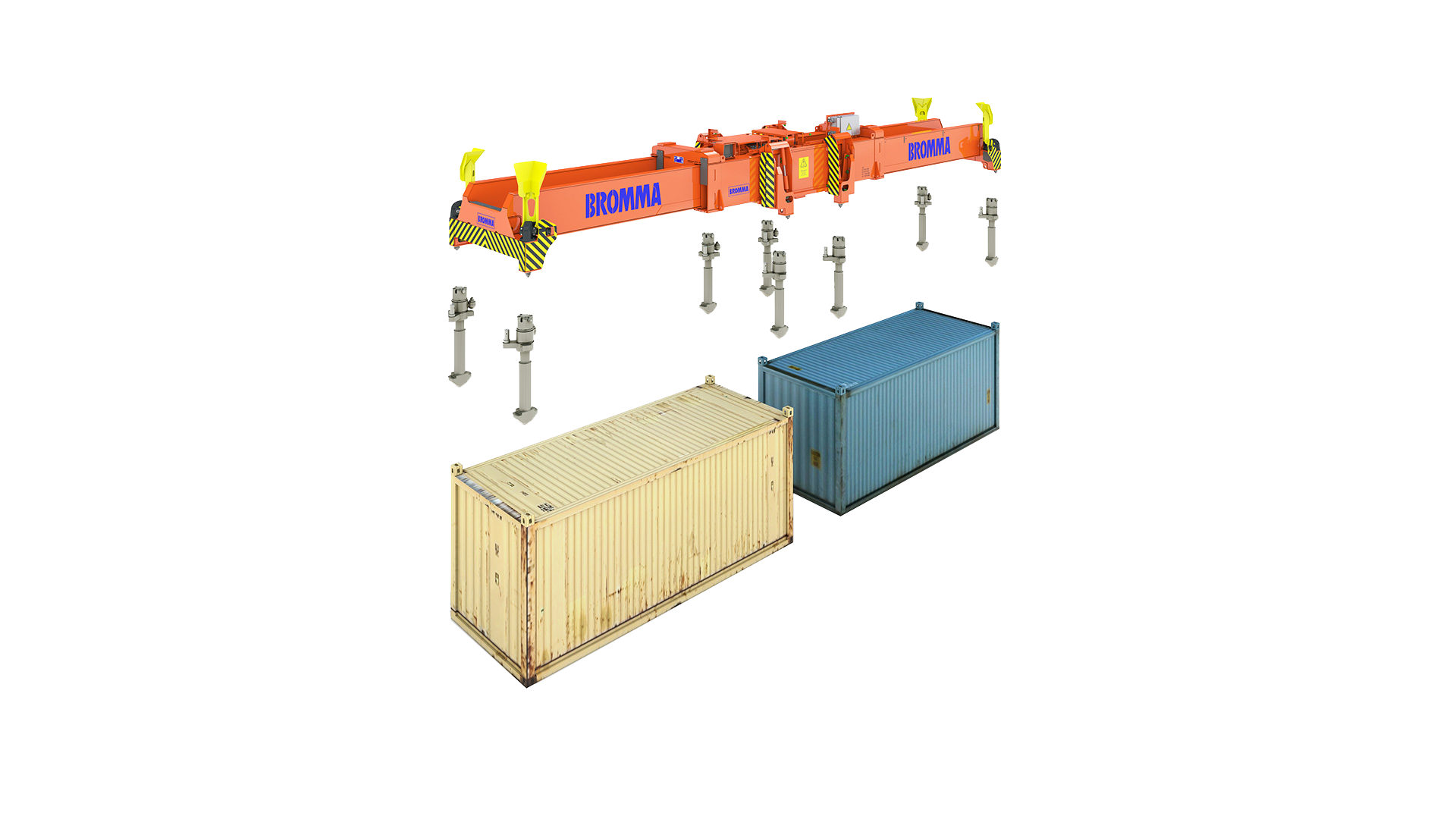

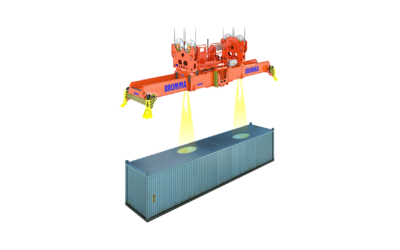

The Bromma Load Sensing System weighs containers with high accuracy as part of the normal lifting cycle.

The application can weigh individual containers when lifted, even in twin-mode. The system and weighing process will have no effect on the cycle time and operational flows in the terminal. The Bromma Load Sensing System provides increased safety during operation, certified and accurate weighing suitable for container weight verification, overload detection and eccentric lift detection. The Bromma Container Weighing system is certified (Type Approved) to OIML R51 as well as to 2014/32/EU (MID). For details about classification and characteristics related to the certification, please see special information document*.

*Document ”Application Description/Container Weighing” is available on www.bromma.com or from your local Bromma representative.

The customer specific set of data required is specified during installation of the system. Data available include i.a.:

- Total container weight under the spreader

- Weight of the left/right container (in twin-lift)

- Individual twistlock load

- Eccentricity under the spreader

- Eccentricity of the left/right container (in twin-lift)

- Eccentricity warning

Specifications

Scope of work

The scope of work in the supply and installation of the Load Sensing System upgrade is as listed below:

- Software installation

- Modify program for spreader/group of spreaders

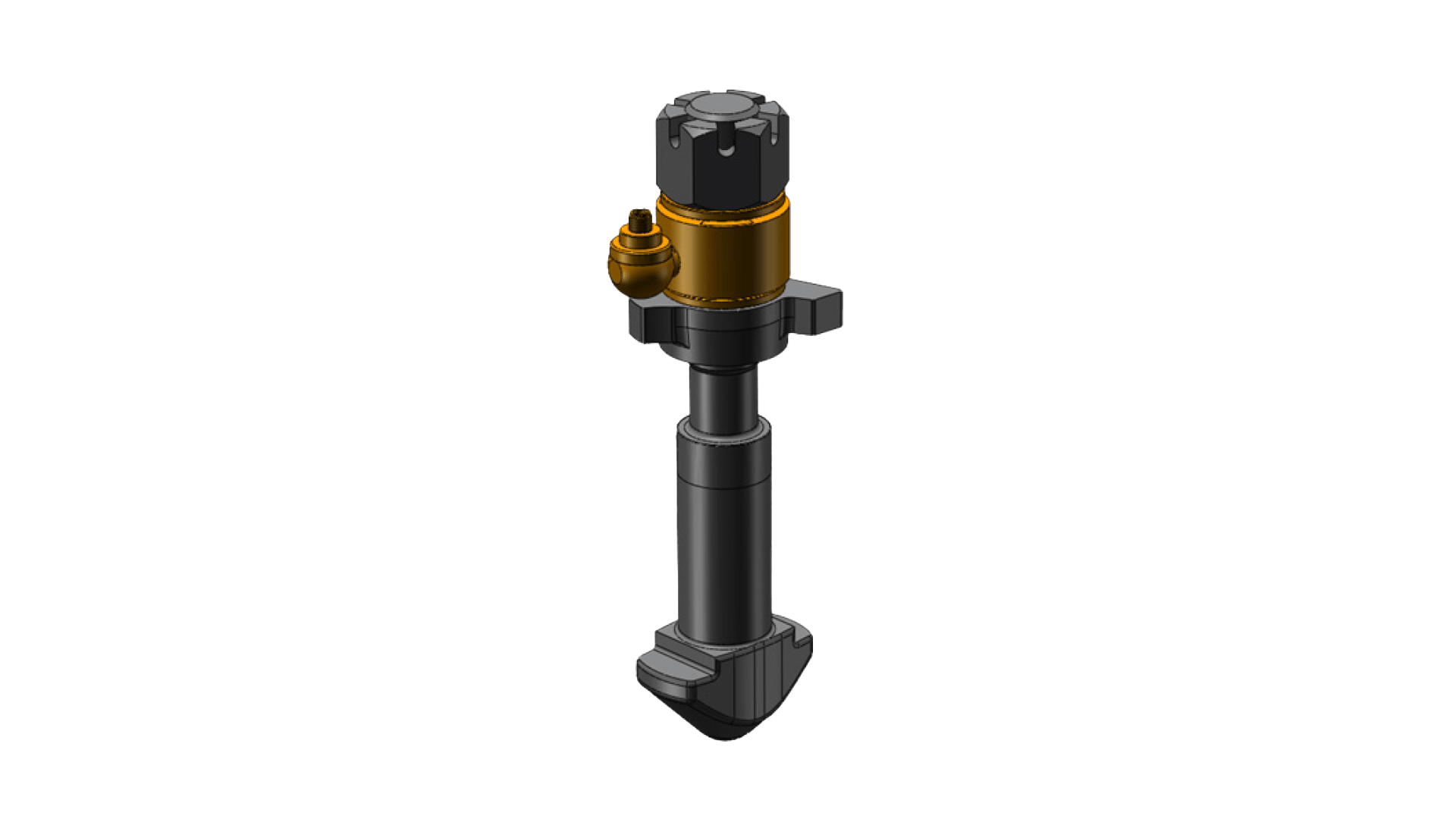

- Dismount existing twistlocks

- Mount new twistlocks and load cells

- Installation of controller for spreaders w/o SCS3 or SCS4

- Wiring to electrical cabinet installed

- Wire load cells

- Rewire CANopen modules

- Run wires to distribution blocks

- Program controller and display accor- ding to project

- Update drawings and spreader manual

- Test all functions

Parts included

The following parts are included in the Load Sensing System upgrade offered:

Load Sensing kit

- Load sensors (1 per twl)

- New twistlock pins and nuts

- New sensor mouniting brackets

- CANopen nodes and cabling

- Mounting details

- Software upgrade

- Stand-alone kit and controller (for non-SCS3/SCS4 spreaders)

- Cabinet with all components

- Cables

- Distribution blocks

Booster kits

- Booster kits on headblock and crane to amplify CANH and CANL signals for uninterrupted two wire communication

Anybus gateway

- Anybus Crane gateway (required if the weight data is to be sent to the crane PLC)

Filter kit

- Filter to reduce noise in communication lines for transmission of data

Additional items included in scope of work

The following additional items will be included in the Load Sensing System upgrade:- Software update on port’s computer that will be used to connect to the stand-alone display and controller.

- Load Sensing System training.

Optional items

Crane cabin monitor

- 7” Color Graphics display for mounting in the crane cabin including cabling and the necessary devices to connect to the crane/spreader communication bus (brackets for installing the display in the crane cabin are not included).

Note!

- Boosters and filters are optional and not included in the standard upgrade offering.

- If other control system than SCS3 or SCS4 is used – a separate controller will be needed.

- Anybus Gateway can be replaced by Bromma Connect (see separate information).

- The system cannot be combined with the INRS damping system or corner rollers.

- This is a general list of the parts needed for the kit, the quantities of each are not shown and. they may vary depending on the project.

Price, leadtime & delivery

- Installation leadtime is 3 days per kit including testing. Please connect with your local Bromma representative for price and delivery/material leadtime.