Digsy/Relay/SCS² (non-CANopen) to SCU with RML

Description

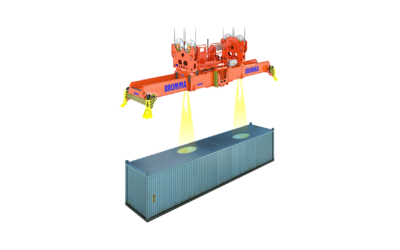

The upgrade from Digsy, relay or SCS² (non-CANopen) control system to SCU with RML offers a greater solution to spreader control, monitoring and troubleshoo-ting efficiency.

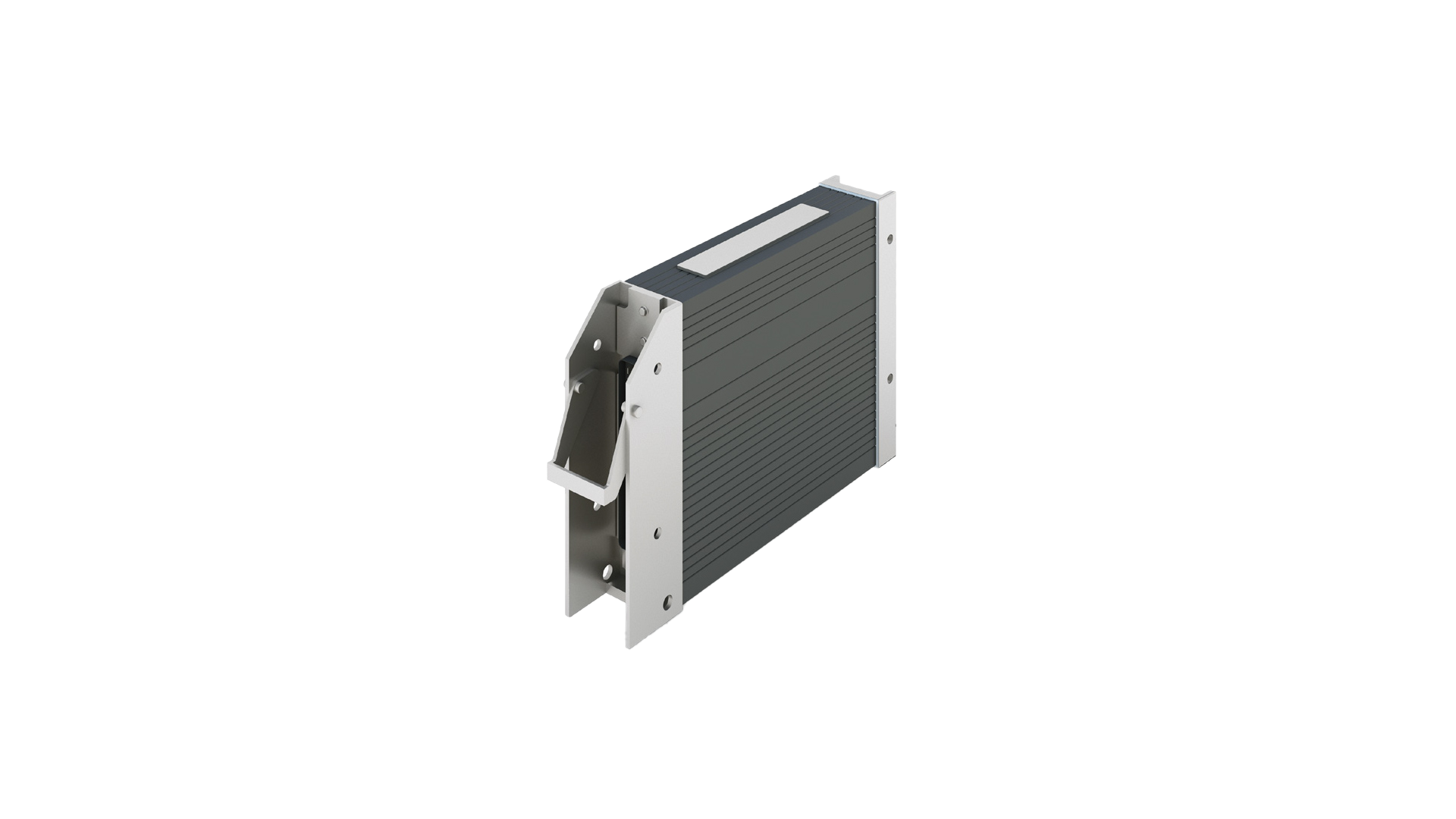

The Bromma Spreader Control Unit (SCU) is a spreader control system developed to focus on the core functionality needed to control and operate a Bromma spreader. The SCU is mounted inside the electrical cabinet and consists of two basic ele-ments; a spreader mounted PLC and the spreader control software which controls the spreader functions.

The result is a single control system optimized for spreader control.

The Remote Monitoring Log unit (RML) provides essential diagnostic spreader information from the spreader unit connected to it. It is mounted near the electrical cabinet and has a communication reach of approximately 50 meters (depending on surroundings).

Spreader information can be accessed on an encrypted webpage from any WIFI-equipped laptop, tablet or smartphone. This enables service and ma-intenance personnel to review and analyze data in order to further improve spreader productivity.

Benefits of the upgrade

- The SCU communicates with the crane PLC through a parallel I/O interface, and a serial CAN bus interface, supporting DS444 and BCAN.

- A separate CAN bus interface is utilized to manage the on-board I/O, i.e. sensors, actuators, etc., which minimizes the need for junction boxes, relays, wiring and terminals.

- The software is built-up by using Bromma proven function blocks and system functions, minimizing configuration needs.

- The applications which control the spreader can be easily adapted according to customer requirements.

- The RML provides crucial diagnostic signals and commands from the crane interface which are monitored and displayed in real time.

- Clear symbols and text displayed enables quick understanding of the type of event and the action needed.

- The permanent diagnostic logfile is able to store up to approximately 1.8 million events, which can be used for further analysis.

Specifications

Scope of work

The scope of work in the supply and installation of the upgrade from Digsy, relay or SCS2 (non-CANopen) control system to SCU with RML is as listed below:

- Write programs for spreader or group of spreaders

- Write instructions for installation

- Weldment mounting instructions

- Remove old parts

- Install new parts as per instructions

- Wire all components

- Download spreader program to PLC

- Revise existing drawings

- Revise spreader manuals

- Test all functions

Parts included

The following parts are included in the Digsy, relay or SCS2 (non-CANopen) control system to SCU with RML upgrade offer:

- SCU PLC

- SCU control cable

- RML

- Converted and updated spreader program

- CANopen cables

- CAN Encoder (for APS positioning)

- CR9056 planks

- Plugs

- Proximity switches (for DPS positioning)

- Cables and item markings

- I/O modules

- HTS protection covers

- X100 cabinet

- X1 cabinet

- Current relays

- Proximity switches

- LED lamps

- Resistors

- Gland adapters

- Electrical cables

- Connectors

Additional items included in work scope

The following additional items are included in the Digsy, relay or SCS2 (non-CANopen) control system to SCU with RML upgrade:

- Install software on the port’s computer that will be used to connect to the spreader

- Firmware update of components and spreader control system

- SCU and RML training

Material & installation leadtime

- Please contact your local Bromma representative for material and installation leadtime.

Price & delivery

- Please connect with your local Bromma representative for price and delivery leadtime.