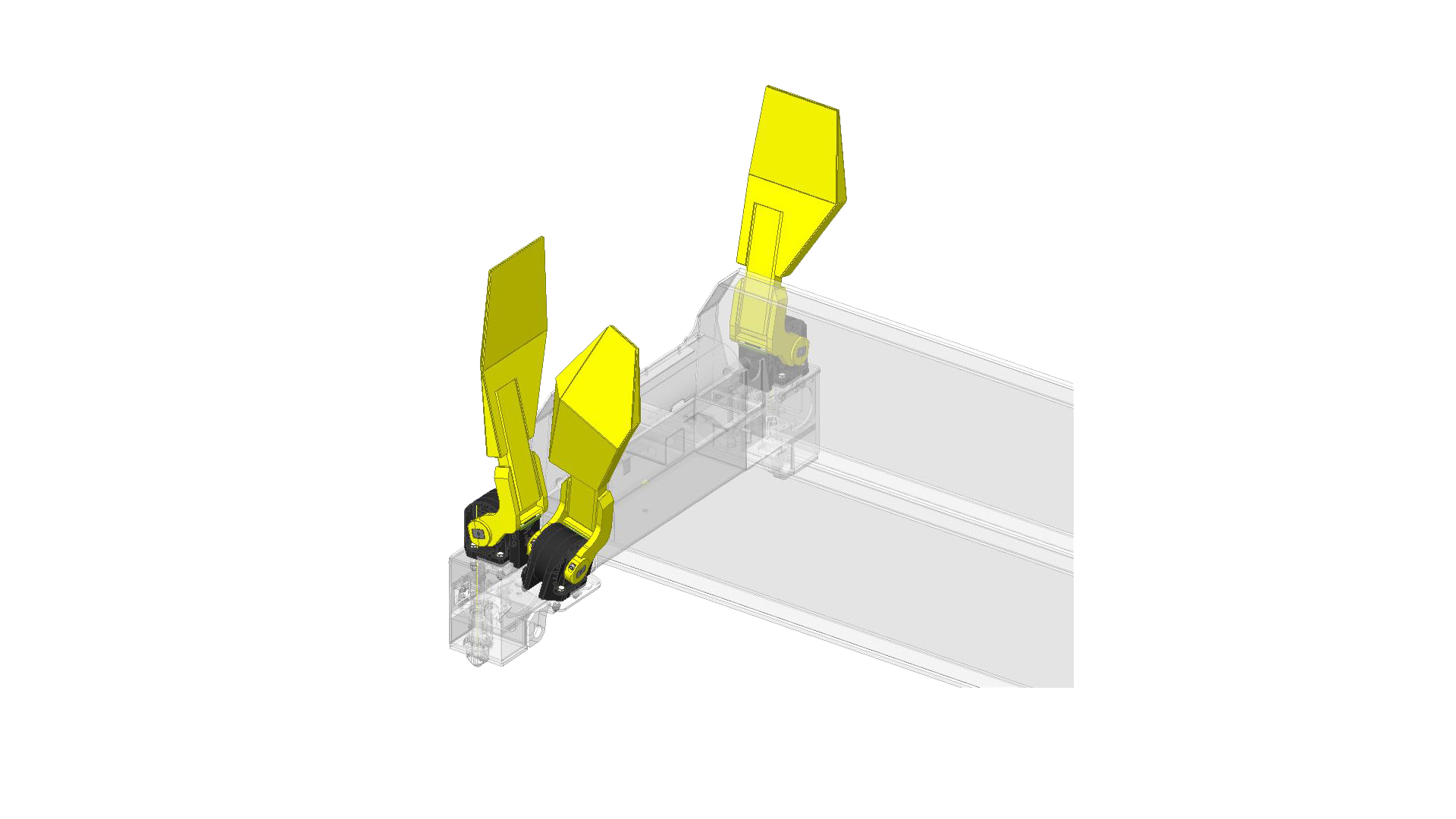

Six Paddle Flipper Arms

Description

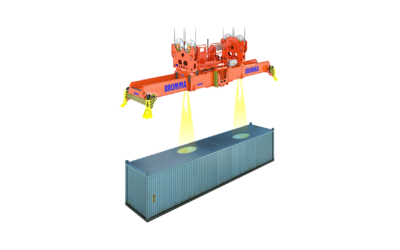

The Six Paddle Flipper Arms configuration is a preferred option by terminals and crane operators as the extra paddles increase spreader placement accuracy and thus can enhance speed when transporting containers.

This upgrade is available both as an option for new spreaders, or as an upgrade on existing spreaders. Additional mechanical modifications are needed to retrofit the base design for spreaders with Four Corner Flipper Arms.

Benefits of the upgrade

- Preferred by terminals as it can increase operational speed

- Offers increased flexibility and ease of operation

- Improves accuracy in spreader placement

Specifications

Scope of work

The scope of work for the supply and installation of the Six Paddle Flipper Arms design upgrade includes:

- Remove existing flipper gearbox and motors

- Install new plate

- Modify manifold block

- Cut and weld material and plates on spreaders

- Weldment mounting instructions

- Wire all components

- Write instructions for installation

- Change programming

- Install new program

- Test all functions

- Revise existing drawings

- Revise spreader manuals

Parts included

The following parts are included in the Six Paddle Flipper Arms upgrade offer:

- Rib plates

- Top plates

- Spacers

- Hydraulic blocks

- Flipper arms

- Directional control valves

- Check valves

- Restrictors

- Couplings

- Hoses

- Manifold blocks

- Cables

Additional items included in work scope

The following additional items are included in the Six Paddle Flipper Arms upgrade:

- Software update on port’s computer which will be used to connect to the spreader

- Firmware update of components and spreader control system

- Operational and maintenance training

Material & installation leadtime

- Material leadtime: 5 weeks (Exw Bromma Malaysia)

- Installation leadtime: 5 days (per spreader, inclusive of testing)

Price & delivery

- Please connect with your local Bromma representative for price and delivery leadtime.