SLC40T

Description

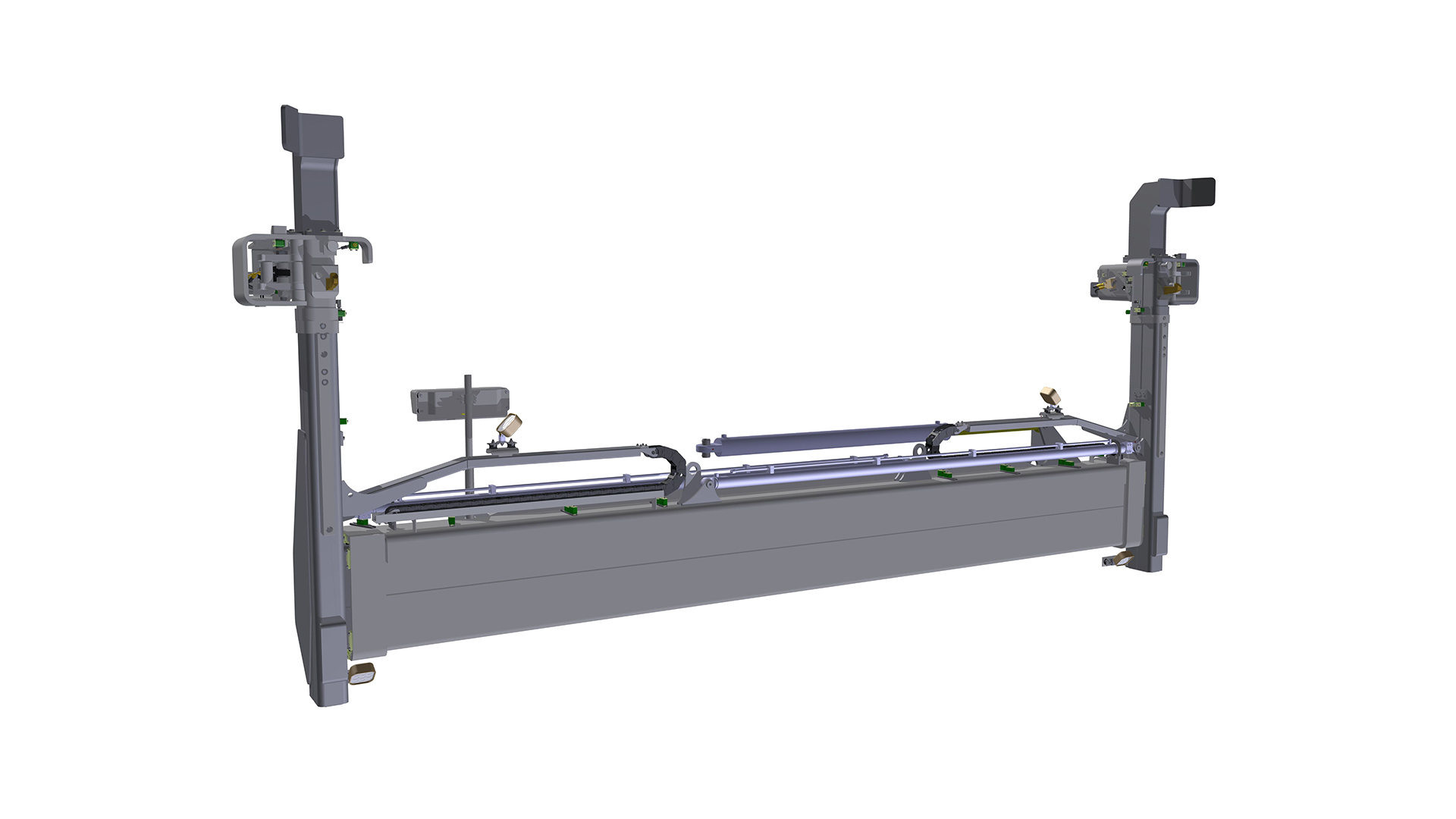

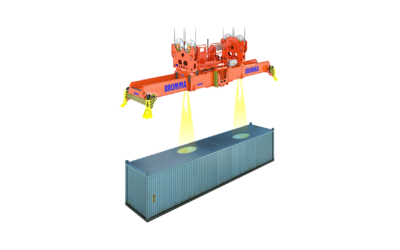

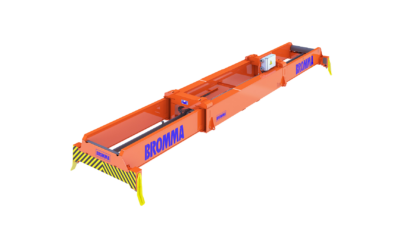

The Bromma SLC40T is a twinlift side spreader for simultaneous handling of two empty containers for masted lift trucks.

The visual contact with the stack, container corners and hooks has been optimized to allow rapid positioning of the lifting heads to the container. SLC40T is equipped with side shift, telescopic and mechanical pile slope functions that allows it to easily locate containers. It uses hooks and side clamps to secure the container. The hooks engage the top of the bottom container, and the side clamps lock into the corner castings of both containers.

All spreader movements are controlled with 24V proportional valves, providing precise and smooth operation. The spreader is operated from the driver’s cab over serial communication (CANopen) or parallel wiring. Commands are processed by an electronic control unit on the spreader with built in safety logics for container handling.

The spreader is designed in accordance with EN13001. As all Bromma spreaders it is made from European high quality steel, which ensures a light and robust design. The spreader has a user friendly design and all components are easily accessible for inspection and maintenance.

Major Features

- Higher visibility and better efficiency

- 20’ to 40’ at maximum speed with dampening

- Suspended lifting hooks with side clamps

- ± 600mm side shift

- Up to ± 6° Powered Pile Slope

- Full CANopen bus integrated management

- Longer service intervals and long economic life

Specifications

Lifting capacity(SWL)

- 10 metric tons, up to ±10% eccentric load

Tare weight

- 9T model = 4 000 kg (spreader only), ~1 700 kg for the sideshift carriage

- 11T model = 4 300 kg (spreader only), ~1 700 kg for the sideshift carriage

Suspended lifting hooks

- 2 pieces

Side shift

- ± 600 mm with smooth control technology

Powered pile slope

- ±6° PPS in sideshift carriage in combination with 250 mm float & spring loaded vertical heads

Telescoping

- 20’ to 40’ in less than 15 sec. Analogue or digital sensors for damping and telescoping.

Mechanical pile slope

- ±5°