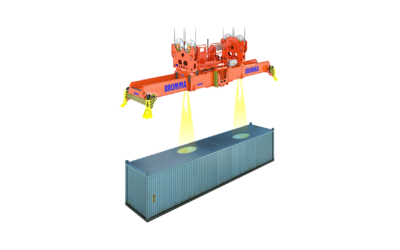

Autolubrication System

Description

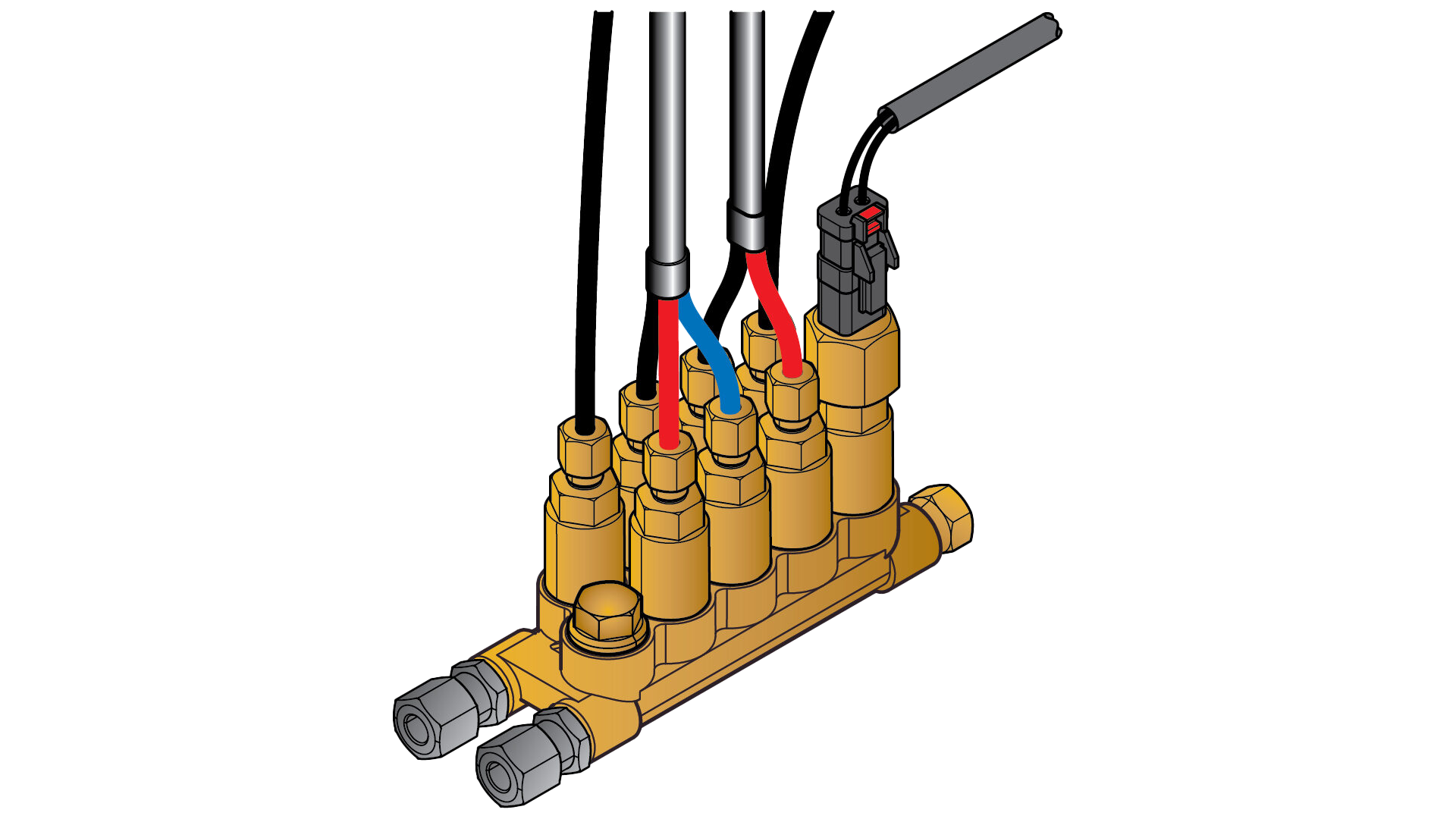

This dual-line automatic greasing system consists of a robust plunger pump, two main lines to the distribution blocks with metering units and secondary lines to the individual lubrication points. The grease is pumped to the distribution blocks via a double main line network. The metering units supply the exact right amount of grease to each lubrication point. The pump will only switch off once the pressure in the entire system is at least 100 bar. As a result, the right amount of grease is always provided to each lubrication point, independent from counter-pressure, temperature or grease viscosity.

Benefits of having the Autolubrication System upgrade are:

- All lubrication points are automatically lubricated, thus reducing the need for service and maintenance

- Grease output and grease dosing independent of ambient temperature and grease viscosity

- Equipped with a follower plate that ensures all the grease in the reservoir is used. This means that the reservoir wall remains clean, allowing to check the grease level visually. Ageing of the grease as a result of oxidation is also prevented

- Thanks to the low work pressure, the quality of the grease is preserved

- Corrosion resistant thanks to unique brass metering units and distribution blocks

- The predetermined lubrication cycle can be adjusted to accommodate the terminal’s needs

- The system is operated by the spreader control system

Specifications

Scope of work

The scope of work for the supply and installation of the Autolubrication System upgrade includes:

- Install the autolubrication system

- Install the timing programme

- Test the equipment

- Revise existing drawings

- Revise spreader manuals

Parts included

The following parts are included in the Autolubrication System upgrade offer:

- Autolubrication system

- Divider block

- Hoses

Additional items included in work scope

The following additional items are included in the Autolubrication System upgrade:

- Software update on port’s computer that will be used to connect to the spreader

- Autolubrication system training

Material & installation leadtime

- Material leadtime: 5 weeks (Exw Bromma Malaysia)

- Installation leadtime: 3 days (per spreader)